Using a flood and drain system is an excellent hydroponic option to grow mass quantities of small plants because no individual feeder lines are required. In fact, I cannot think of an easier way to do so. Thus, if you have small seedlings or clones, this makes it very efficient to have them put on a flood table until they are transplanted to another system.

Although you could grow large plants on a flood table, there are many other cheaper options like top feeding in buckets that may send you using alternative methods; if large plants or long rows are among your plans.

Building a Flood and Drain System

Flood Table Materials

1. Flood table made to size or plastic store-bought model.

2. Two 1/2-inch poly elbows.

3. Two 1/2-inch poly Ts.

4. One roll of 3/4-inch tubing.

5. Two 3/4-inch thru-hull fittings.

6. One reservoir (should hold about 12 gallons of fertilized solution per each 4×4 table space).

7. Plastic covering for tray, or a growing medium such as perlite, perlite / vermiculite, coco fibers / perlite, or expanded clay.

8. Pump (250 to 350 mag drive for 4×4 to 12×12 space. Stronger pumps can be used for larger tables.)

9. Panty hose to cover pump (optional).

10. 3/4-inch plywood to support table.

11. Four sawhorse hinges per table.

12. Eight pieces of 2×4 cut to identical lengths for the legs. The table height should be slightly higher than the reservoir.

13. Two pieces of 2×4 for table support. These will connect two sets of legs.

14. 1/2-inch poly-threaded female fitting to attach to pump.

15. Intermittent timer.

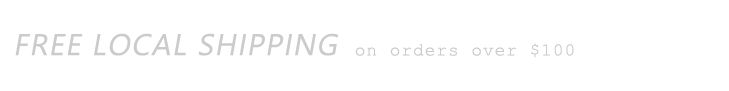

Tools

1. Drill.

2. One-inch hole saw.

3. Saw.

4. Pipe wrench or crescent wrench.

5. Knife.

Setting Up the System

A. 2x4s should be cut to length so that when the sawhorse legs are set up, the reservoir will be slightly lower than the table. Each pair of sawhorse brackets will be joined with another 2×4 to give the table support.

B. Flood table is placed on the 3/4-inch plywood.

Making a Homemade Flood Table

If wood is used to make a flood table, it should be 3/4-inch plywood. Anything thinner will warp.

Once plywood is cut to size, 1×4-inch wood should be nailed to the sides. For simplicity, the following instructions assume that a 4×8-foot sheet of plywood is used for the table.

Two 8-foot lengths of 1×4-inch wood should be nailed to the long lengths of the plywood.

One 8-foot length of 1×4-inch wood that is cut in half can be used for the short sides; then the small sides are nailed together from the bottom of the plywood.

Caulking should be applied along the nailed seams for extra waterproofing.

The table should be placed on something that supports it. A quick sawhorse can be made with cheap 2×4-inch wood and with hinges that the 2×4-inch wood slides into. Another 2×4 (i.e. an eight footer for an 8 to 4-foot flood table) is placed between the hinges to complete an instant sawhorse. One end should be an inch or so higher than the other end so that the solution can be recirculated.

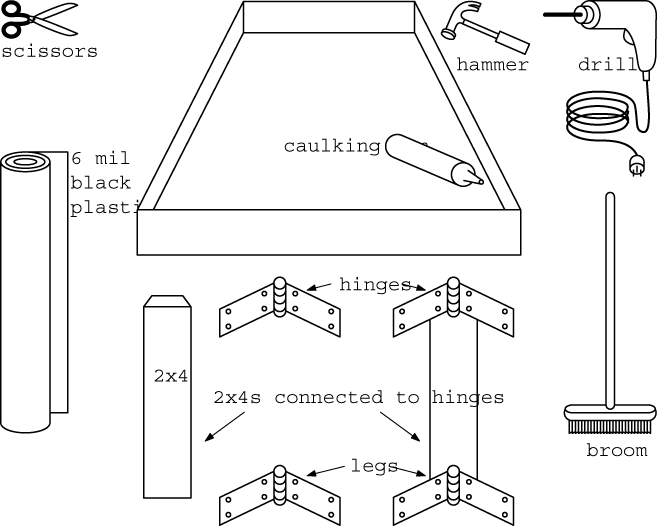

In the middles of the two widths, two holes should be made about 2 inches from the end of the table using a 1-inch hole saw. Diagram shows a table with tubing connected to thru-hull fittings underneath the table.

Now, two layers of 6ml black poly plastic should be used to cover the bottom and sides of the table.

The spots where the holes should be made will be obvious if the table is store-bought.

A thru-hull fitting is inserted into each hole. Extra care is needed in the homemade flood table: the plastic should be carefully drawn through the thru-hull fittings and the hole in the plywood by making a small hole in the 6ml plastic. When the thru-hull fitting goes through the table, black 6ml plastic should be seen tightly secured against the threads of the thru-hull fitting.

Now the plastic can be cut out from underneath the table, and the female fastener can be used to tighten the thru-hull fitting to the flood table. Now the system will be leak-free. Care must be taken so that top layer of plastic does not get cut open. If the top plastic layer has a hole, water can leak into the bottom plastic layer. This will create a balloon-like effect from the trapped water. Cutting plastic away from the thru-hull fitting can prevent water from trapping between the plastic layers.

C. The pump is placed in the bottom of the reservoir and a 1/2-inch female fitting is attached to the pump.

D. Two 4-inch pieces of 1/2-inch tubing are connected to the thru-hull fittings (for holes that are made at the ends of the tables). Heating the 1/2-inch tubing with hot water will make the connection easier. The next step is connecting two 1/2-inch elbows to the 1/2-inch tubing. Then, 1/2-inch black poly tubing is connected to each end of the elbows. When the two ends of the black poly tubing meet in the middle, a T-fitting should be inserted; this can be run to the pump.

E. The pump is connected to 1/2-inch tubing. Just above the pump, a piece of the 1/2-inch tubing should be cut out and a 1/2-inch T should be inserted. The exposed end of the T should be connected to 1/2-inch tubing and then to an on/off tap that will act as a bypass valve. Another piece of 1/2-inch black poly tubing can be connected to the end of the tap, followed by an elbow so that solution splashes and is aerated without making any mess.

Feeding

F. Method A (for small to large plants)

1 to 4-gallon containers (mesh pots) can be placed on the table and filled with soilless mix (such as Sunshine #2 mix). The plants should at first be top-fed continually (for fastest growth) or periodically (slower growth with a lot less maintenance) until the roots are visible at the bottom of the container.

When the roots are visible at the bottoms of the containers, a grower has two options.

1. Put a 1-inch layer of perlite on the table. The feeding intervals can be once a day or more often. One study done under identical growing conditions showed yields that were almost identical between one batch that was fed continually and the other batch that was fed in the morning. Perlite holds air and moisture with nutrients in between feedings.

2. Put a sheet of reflectix material on top of the flood table with holes cut to size to fit the containers. Reflectix will help keep the roots cooler. The reflectix can be used with or without perlite undernearth, but if there is no perlite, a grower should feed a few times a day. If perlite is used, one feeding a day is all that is required.

Method B (for midsize to large plants)

A custom-sized sheet of reflectix material is precut. This material will cover the table and will fit securely over each slab. The slabs are placed under the holes with a secure fit.

When the clones are ready for transplanting, they should be placed into the 1-foot rockwool slab. A grower should do the first couple of feedings from the top until the roots reach the bottom of the slab, or he could allow the table to flood lots of solution for the first couple of feedings.

Flooding and draining should be done several times a day at a water level over 1/4-inch. Six or more floods at regular intervals should work. A timer is used to control the period for which the flooding takes place. The time depends on the flow rate and and size of the table. Using a wristwatch and a couple of manual floods will give a grower the amount of seconds that need to be programmed into the timer so that the solution fills the table to the desired level.

A little extra tip: most hydroponic feeding systems can be converted to aeroponic systems with a high-pressure pump, misters / feeder lines to mist the roots and / or leakproofing, if necessary.