The bucket system is a productive way to grow large plants and recirculate the solution. Plants like peppers and tomatoes are two such kinds of plants that can thrive in systems like this.

Building a Top Feeding Bucket System

Option B: Bucket System

Tools

1. Drill and 1-inch hole saw.

2. Knife.

3. Wrench.

Materials

1. One 3 to 4-gallon mesh pot or one solid 3 to 4-gallon bucket per plant.

2. One 5-gallon bucket per plant.

3. One to two 3/4-inch thru-hull fittings per plant (one for mesh pot, two for solid buckets).

4. One 3/4-inch T per plant.

5. 3/4-inch yellow flex hose (enough to connect plants together and to connect to reservoir).

6. One reservoir with 3/4-inch thru-hull fitting in the bottom.

7. One 3/4-inch T.

8. One roll of 1/2-inch black poly tubing.

9. One roll of 1/8 or 3/16-inch black poly tubing.

10. One fitting per plant to connect 1/2-inch tubing to 1/8 or 3/16-inch tubing.

11. One alligator stake per plant.

12. One 1/2-inch T fitting.

13. One 1/2-inch end cap.

14. One to two 1/2-inch elbows.

15. One 1/2-inch female threaded fitting for pump.

16. One pump.

Support System: Building the system

Plants grown in a bucket system in the closet do not need much time for vegetative growth before flowering. However, plants grown to the ceiling in a larger room will need more time to complete the whole cycle.

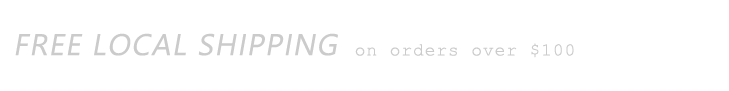

With a bucket system, a mesh pot or bucket (with plant and growing medium) is stacked into a 5 to 7-gallon pail.

A. If a bucket is used, a 3/4-inch thru-hull fitting should be inserted into the bottom so that solution can drain into the bottom pail.

B. The bottom pail should have a 3/4-inch thru-hull fitting in the side near the bottom. If this hole is too low, the thru-hull fitting won’t fit.

C. A short piece (approximately 6 inches) of 3/4-inch yellow hose should be attached to the 3/4-inch thru-hull fitting.

D. A 3/4-inch T should be inserted into the other end of the hose.

E. The open ends of the T should be connected to other buckets with yellow flex tubing.

F. After all buckets are connected, there should be two open ends from the 3/4-inch T fittings attached to two of the buckets. The final stage is to attach these fittings to hose, then to attach both ends of hose to another 3/4-inch T. Then the hose is connected to the 3/4-inch thru-hull fitting on the bottom of the reservoir. The reservoir should be located lower than the pails so the pails drain well.

G. A piece of 1/2-inch poly tubing (feeder line) is cut and laid near the plants.

H. A 1/2-inch end cap is inserted at the end away from the reservoir. Soaking tubing in hot water allows for easier connections.

I. A 1/2-inch poly elbow is inserted at the open end that is nearest the reservoir. The elbow should be directly above the reservoir.

J. 1/2-inch black poly tubing should be connected to the other end of the elbow and then to the pump. A highly recommended option is to put a bypass valve or a 1/2-inch T just after the pump so that the solution stays aerated and agitated, and the flow can be controlled. More 1/2-inch fittings can be placed on the bypass valve so that the aerated liquid is forced to the bottom near the pump. Also, forcing water downward can reduce possibilities of splashing and making a mess on the floor.

K. Small holes should be poked into the 1/2-inch poly header line that is on the flood table. A punch or small drill bit can be used to make the holes for the fittings.

L. 1/8 or 3/16-inch tubing is connected to the fittings and secured to each pot using alligator stakes. It is best to look ahead to see where the plants will be when it is harvest time so that the proper lengths can be cut.

Feeding

It is easiest to feed the plants with the pump timer running full-time only during the light hours. A solar pump would allow for this. But plants can be fed continuously (all day and all night). Also, plants can be fed intermittently (i.e. every 20 minutes for 2 minutes) during the light hours, or for all hours.

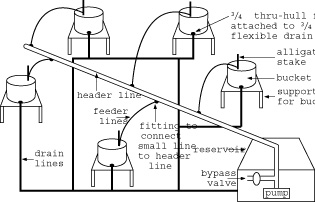

Hydroponic to Aeroponic Conversion

Many top-feeding hydroponic systems can be converted to aeroponic systems by using a stronger pump, adding a mister for each plant, and changing the position of the mister to feed roots in the air (under the lid) as opposed to top feeding. Hydroponic systems that use less growing medium will work best, such as those grown in PVC or gutter pipe.

In this case, a small, say, 6-inch mesh pot will be used to replace the old 3-gallon bucket. The mesh pot with a small amount of growing medium should then be placed in a lid. Then the mesh pot gets inserted into a 5 to 7-gallon pail. Adding a mister for each bucket (to feed inside the pail) and a high-powered pump completes the conversion. A small hole must be made in the 5 to 7-gallon pail to accommodate the tubing and mister. 1/8 to 1/4-inch tubing and matching misters are good sizes to use with the conversion.

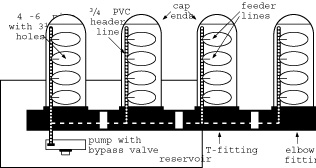

Option C: Top Feeding with PVC or Gutter Pipe

Tools

1. Drill and 31/2-inch hole saw.

2. Knife.

3. Wrench.

4. Handsaw or skill saw.

Materials

1. One small mesh per plant (i.e. 31/2 inches).

2. Two sawhorses to support the 8 to 12-foot lengths of pipe.

3. One alligator stake per plant.

4. One 1/8-inch fitting per plant.

5. One piece of 1/8-inch tubing connected from header line to an alligator stake per plant.

6. One reservoir.

7. Two 6-inch elbow fittings.

8. Six-inch pipe cut to equal lengths that are used to hold the plants.

9. Six-inch T-fittings for each length of 6-inch pipe, less the last pipe.

10. Mag drive pump.

11. Bypass valve.

12. 1/2-inch black poly tubing for header lines.

13. Two 1/2-inch black poly elbows.

14. 1/2-inch black poly Ts for each pipe, less the last pipe.

15. 1/2-inch black poly end cap for each that runs inside of the 6-inch pipe.

16. One 6 to 10-inch piece of PVC to connect drain line.

Procedure

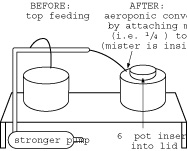

A. The 4 to 6-inch pipe will be placed on something that supports it. A quick sawhorse can be made with cheap 2×4-inch wood (i.e. 2 to 3-foot lengths) with hinges that the 2×4 wood slides into. Another 2×4 (i.e. an 8-foot length) is placed between the hinges to complete an instant sawhorse.

B. Two (or more) sawhorses can be used to support the connected pipes. Two sawhorses support an 8 to 12-foot length of 2×4-inch wood.

When the sawhorses are made, the side furthest from the reservoir should be the highest and at equal height. The side nearest the reservoir should be an inch or so lower for every 8-foot length so that the solution drains back into the reservoir.

C. All piping (i.e. 6-inch PVC) should be cut to the desired length.

D. Holes (3 1/2 inches) should be cut in the pipe at the desired spacing (i.e. 8 to 12-inch centers). The hole sizes must match the pot sizes in order to make a custom fit.

E. All lengths of large pipe must have end caps attached to the higher ends (i.e 1-inch higher) that are located at the far side from the reservoir.

F. 1/2-inch poly tubing should be run along the inside of the pipes until it reaches the end. It should be cut to a length that reaches the middle of the T-fittings and elbow fitting that will be connected to the larger pipe at the shorter end. The 1/2-inch poly tubing must have a 1/2-inch end cap at the end. The 1/2-inch poly tubing should have small holes punched into the tubing at the desired spacing (i.e. 10-inch centers); it should have fittings (i.e. 3/16, 1/8, 1/4-inch) inserted into each of the holes; and it should have a feeder line connected to the fitting.The appropriate sized tubing should be connected to the fittings in the header line. For example, 3/16-inch tubing should be connected to a 3/16-inch fitting. The tubing should be cut to a length that will reach the larger hole (for the pots) and with slack.

G. Small holes should be drilled into the pipe for the feeder tubing (i.e. 1/8, 3/16, 1/4-inch tubing) to be fed through. The hole should make for a snug fit.

H. All large 6-inch pipes (except the last pipe) are connected to their neighboring pipe with T-fittings. For example, 6-inch pipe will use 6-inch T-fittings. Small pieces of 6-inch pipe are placed between the T-fittings in order to connect the T-fittings and give the desired spacing (i.e. 10-inch centers).

I. The last pipe will have a 6-inch elbow fitting that connects to the 6-inch T-fitting of the second to last pipe. 6-inch pipe is placed between the 6-inch fittings.

J. The first 6-inch T-fitting (above the reservoir) can be connected to an elbow, then connected to larger pipe in order to send the solution downward into the reservoir without making a mess. A small piece of pipe is placed between the 6-inch T-fitting and elbow to secure the connection.

K. Another 1/2-inch poly line will run down through the 6-inch T-fittings and into the last elbow fitting of the large 6-inch pipe above the reservoir. This tubing will be connected to the other 1/2-inch poly tubing that runs through the lengths of pipe. All 1/2-inch tubing should have a 1/2-inch T-fitting inserted at the desired spacing (i.e. 10-inch centers), except for the very end. The very end will be attached to a 1/2-inch elbow. All of the fittings should be inserted before 1/2-inch tubing is run along the insides of the larger 6-inch T-fittings and elbow.

L. The 1/2-inch poly line with the 1/2-inch T-fittings and 1/2-inch elbow fitting should be run along the inside of the larger 6-inch T-fittings and elbow fittings.

M. The large 6-inch elbow fitting at the end (away from the reservoir) should be removed. The 1/2-inch elbow should be connected to the 1/2-inch line that runs through the inside of the large 6-inch pipe. Then the large 6-inch elbow and 6-inch T-fitting is reconnected. Piping and fittings can be glued with PVC cement (for PVC) pipe, but, the connections will be permanent. The system will not leak without glue; a little bit of duct tape can be used for securing connections so that disassembling is easy.

N. Each 6-inch T-fitting (starting from back to front) should be removed one at a time. When the 6-inch T-fitting is removed, the 1/2-inch poly lines should be connected together at the 1/2-inch T. Then, the larger pipe fittings are immediately connected back together after the smaller 1/2-inch tubing is connected to the inside of the larger T-fittings. Piping and fittings can be glued with PVC cement (for PVC) pipe, but, the connections will be permanent. The system will not leak without glue; a little bit of duct tape can be used for securing connections so that disassembling is easy.

O. At the first pipe (above the reservoir), there will be an open end of a 1/2-inch poly T. This loose end should be attached to a small piece (i.e. 3 inches) of 1/2-inch poly tubing. This tubing is connected to a 1/2-inch poly elbow. A proper length piece of 1/2-inch poly tubing is connected to the 1/2-inch elbow and connected to the pump. A 1/2-inch female fitting may need to be attached to the pump in order to connect the 1/2-inch tubing. This 1/2-inch tubing runs in the inside of the larger 6-inch piping.

P. Recommended Option: A 1/2-inch poly T should be inserted a few inches above the pump that sits at the bottom of the reservoir. A small piece (i.e. 3 Inches) of 1/2-inch poly tubing is connected to the 1/2-inch T. A bypass valve should be connected to the small piece of 1/2-inch tubing in order to control the flow rate.

Feeding

It is easiest to feed the plants with the pump timer running full-time, only during the light hours. A solar pump would run during these hours. But plants can be fed continuously (all day and all night). Also, plants can be fed intermittently (i.e. every 20 minutes for 2 minutes) during the light hours or perpertually.

Aeroponic Conversion

A. Each feeder line (i.e. 3/16-inch) that is connected to a pot is removed.

B. A mister should be inserted to the end of the feeder line. Another small hole should be drilled for the mister to fit into. The holes in the pipe should be made in between the pots. The fit for the feeder line must be snug and secure. If the original line is too short, a new line must be cut and put in its place.

C. The pump should be changed to a high-pressure pump designed for aeroponics. The pump should be the size required for the garden dimensions.

Note: With this aeroponic conversion, plants will need to be top-fed until the roots go through the bottom of the medium. Then the plants can misted intermittently (i.e. every 20 minutes for 2 minutes) during light. hours, and one misting in the middle of darkness.